It’s possible to engrave jewelry on your own with the help of reliable laser engravers. You can choose the best one by considering your needs, budget, and limitations. Here are my top six (6) picks to get you started, plus all the essential information you need!

Personalized items make the best gifts. Nothing says, “I’ve put a lot of thought into this!” more than things customized to your loved one’s liking.

Everyone enjoys jewelry – both men and women. It’s a versatile gift, token, or souvenir item that makes people feel special, especially with personal details on them!

The good news is that you can easily create custom jewelry by yourself. Whether it’s for personal use or extra income, there’s an engraving machine that will suit you.

I’ve compiled 6 of the best laser engravers vouched for by myself, fellow engravers, and online reviews. When put together, this article gives you helpful information before purchasing.

The 6 Best Laser Engraving Machines for Jewelry

These machines cater to different kinds of jewelry engravers. I’ve labeled them based on their highlighted features for easier distinction. Take your pick!

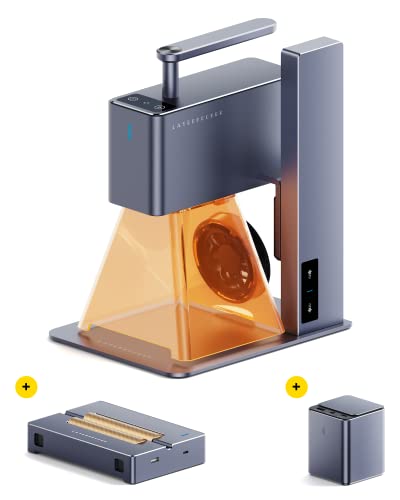

1. LaserPecker 2(Deluxe) Laser Engraver – Best Overall

- 👍Enhanced Experience: The LaserPecker 2 Deluxe...

- 👍360° Rotary/Mobile Engraving: The versatile...

What I Liked

- User-friendly

- Great for beginners

- Good quality hardware

- Reasonable pricing

- Responsive tech support

- Impressive precision

- Controllable from a smartphone

- Handheld tool

What I Didn’t Like

- The software configurations can be improved

- Don’t expect a high-performing machine

This laser engraver is what I’d describe as “small but terrible.” It doesn’t look as intimidating as the big engraving machines, but the hardware is of good quality.

I also appreciate that it can be operated using a smartphone. The convenience improves the overall experience as compared to highly-technical machines.

There’s little to no learning curve with the actual operation. Its software works, but expect some glitches and bugs.

If you’re an artist who sketches your own pattern, the software settings for importation (i.e., from Adobe Illustrator or other popular software options) can be more complicated. It’s best to ask for help from their tech support.

Overall, jewelry-making became MORE EFFICIENT for me with this little tool. It’s a beginner’s friend that actually works and has impressive quality.

2. Triumph Fiber Laser Marking Machine – Best Value

No products found.

What I Liked

- Multiple software compatibilities

- Professional and top-notch quality

- High precision

- Advanced features

- Provides ring engraving parts (informing them is required)

- Reasonably priced for a professional laser engraving machine

What I Didn’t Like

- Pricey for a small business

If you’re not looking for a “toy” and are in the market for the best fiber laser engraving machine with more power, you can count on Triumph to deliver the best quality equipment.

There’s nothing else to say about it, really. When it comes to engraving jewelry, it produces the BEST-QUALITY outputs I’ve ever seen.

This machine can handle everything from gold jewelry to metal jewelry to other hard materials. You can even cut pendants from scratch using this powerful tool.

With its performance and high-speed efficiency, you can also quickly produce multiple custom engraving orders. Many business owners vouch for this laser engraver.

Most CNC machines are expensive, some even costing around $15,000. This Triumph fiber laser engraver costs HALF its price with the same quality and products.

3. ORTUR Laser Master 2 Pro-S2-SF 24V Laser Engraver – Best Budget for Small Businesses

- 5.5W Laser Power & Better at Engraving - Ortur...

- 5 Safety protections - 1. When the laser engraver...

What I Liked

- Good precision

- More affordable

- Easy setup (watching videos is recommended)

- High-quality outputs

- Impressive software compatibilities

What I Didn’t Like

- Complicated for real beginners

For those who have experienced jewelry engraving and would like to upgrade, the ORTUR Laser Master 2 is an excellent middle ground.

It’s not up there with professional laser engraving machines, but it’s also an excellent tool by a known brand. It’s also affordable for a high-quality device, which I appreciate!

The only downside is that real beginners, those starting from scratch, may find this laser machine complicated. It requires a certain skill level to understand the tool thoroughly.

4. Afantti Micro Corded Electric Engraver Pen – Best Engraving Pen for DIY

- 【Stepless Speed】From 3,000 to 20,000 RPM...

- 【Total 30 Bits & 8 Stencils】Includes 2 Collets...

What I Liked

- Very easy to use

- Great for etching

- Cheap

- Good engraver for DIY and free-hand designs

- Lightweight

- Compact

What I Didn’t Like

- For light-duty projects only

- Not the best engraving quality

Since the first few machines aren’t for beginners, here’s a handheld engraving tool that ANYONE can operate. It’s basically a pen tool that’s easy to use as you etch on glass, ceramic, and wood.

One thing to note is that it’s NOT a laser engraver. It’s an engraving pen with no laser technology or laser beam involved. It’s also not one of those cutting tools.

This pen engraver also comes with stencils, so you can be guided with the correct patterns despite being handheld.

I actually prefer tools like this for etching on pendants and more delicate details. It enables a more free-hand engraving process – prone to imperfections but organic and genuine.

It’s also STRAIGHTFORWARD. I love that you don’t need other programs or mechanical expertise to operate this. Anyone can have fun and experience a jewelry engraver.

Of course, don’t expect this engraving pen to work like the other high-end engraving tools. It’s only $16 and is a more low-tech device for simple tasks with minimal power.

5. Dremel 120-Volt Engraver Rotary Tool – Best Handheld Engraving Tool

- Dremel Engraver is ideal for personalizing your...

- Engraves wood, leather, tools, machinery, hard...

What I Liked

- Exceptional quality for a tiny device

- Portable

- Lightweight

- It helps with good hand control

- Affordable

What I Didn’t Like

- Loud

- Hands get tired after prolonged use

- Difficult screws

- Does not rotate

Dremel is the best handheld tool for me. The structure of the engraving pen fits nicely with my hand, making it more COMFORTABLE than other pens. But it still gets strained after a while.

However, despite having “rotary” in the name, the tip doesn’t seem to rotate. It’s more of an up-down motion, like a tattoo pen, if you will!

I didn’t mind since it does the job well, regardless. But if you’re after the rotating feature, you won’t find it here.

Another problem I encountered was the screws. It was challenging to play around with them since they’re small, and you need the right tools for it.

But overall, it’s a decent jewelry engraver and more powerful than other pens. It’s able to etch with precision, and it’s an AFFORDABLE CHOICE.

6. US Stock Raycus 30W Fiber Laser Marking Machine Engraver Metal Stainless Steel – Best for Professional Businesses

- Cloudray exclusively customized the overseas...

- Cloudray Laser's 30W fiber laser engraver is...

What I Liked

- Professional quality outputs

- Responsive seller

- The lightning-fast laser engraving process

- Compatible with Lightburn

- Reasonably priced for a professional engraving machine

What I Didn’t Like

- Standard control board only works with EZCAD Lite

We have another fiber laser engraver on the list, and it’s less expensive by a few dollars. The performance of this laser engraving machine is phenomenal, and I have no complaints!

This tool allows me to engrave small serial numbers on jewelry like a pro. It’s still straightforward and precise, as expected from fiber lasers.

This laser engraving cutting machine is one of the best CNC machines for engraving jewelry. It specializes in engraving hard materials like steel, copper, gold, etc.

A little heads up for EZCAD full-version users, though, the control board that this machine comes in only has EZCAD Lite. You’ll need a separate purchase to upgrade.

If it weren’t for this and the higher price point, I’d say this is the best engraving machine for jewelry overall, particularly if you’re running a business.

Choosing the Best Jewelry Engraving Machine [Factors to Consider]

The best jewelry engraving machine VARIES for everyone. I might find an inexpensive engraving tool helpful for my projects, but a business might need a more heavy-duty machine.

Here are some considerations in finding the right machine for you!

Factor 1. – Type of Jewelry and Material

Jewelry has various kinds of material – stainless steel, metal, copper, gold, or silver. You need an engraving machine that can adequately etch on each type.

There are engraver machines that can’t handle hard metal since engraving metals require more powerful settings that the low-duty tools might not have.

In line with this, I also recommend considering the jewelry size. Are you working with rings, nameplates, or bracelets? There are appropriate sizes for each jewelry engraver.

Figuring out the material and size you’ll work with early on will make machine selection MORE MANAGEABLE and EFFECTIVE.

Factor 2. – Size of Business

Your jewelry engraving machines should match the scale of your business. If running a big company with high-volume orders, invest in a high-end device like Triumph for better sales.

On the other hand, small businesses can use mid-scale engraver machines. These are the ORTUR and Laser Pecker machines.

Factor 3. – Purpose for Engraving

With #2, your intention for engraving must also be considered. If you’re opening a business, getting MORE EXPENSIVE laser engravers and seeing profit returns is the better option.

But if you’re a beginner exploring jewelry engraving, you can start with little pens or handheld tools. These are affordable and straightforward to use.

Another example is if you’re looking to engrave intricate details on jewelry. These minor points might come out better with the precision of a pen tool than with a large machine.

There are endless jewelry-making possibilities, so it’s up to you to determine how your purpose matches the jewelry engraving machines you choose!

Factor 4. – Appropriate Machine Features

Knowing the jewelry material and purpose, you can now look for these specific features in selecting the best jewelry engraving machine.

Some examples are the specifications listed above: laser power, working area, dimensions, precision, and other features.

There are so many good laser engravers in the market. But some jewelry engravers might have advanced features you don’t need or understand, which defeats the purpose.

On the other hand, some engraving machines only work on wood or other “softer” materials and won’t do well with jewelry or metals. These are things to watch out for.

I also suggest looking for jewelry engraving machines with SAFETY FEATURES. An example is that the machine will automatically turn off when it overheats.

Besides being fun, the priority is to have a safe engraving experience.

Factor 5. – Budget Allocations

Finally, your budget is a crucial consideration in the entire process. Jewelry engraving machines are EXPENSIVE; even the cheapest tools will cost us something.

Never spend beyond your means. If you don’t need a high-end jewelry engraving machine, you can always start with basic engraving tools to achieve the same purpose.

If you’re a business, invest in a good jewelry engraving machine to minimize long-term costs and damages.

Factor 6. – Your Skills and Background

As I reviewed these machines, I encountered many complaints about user experience.

Some units are too complicated to use, some people are clueless about software connection, and some can’t even begin to assemble the device.

It’s never wrong to purchase better-quality machines, but it’s best to ensure that you can operate them well to MAXIMIZE their features and technology.

As mentioned, these laser engravers are not cheap. It’s a waste if you’re unable to use them properly.

But that’s not a problem. You can learn all these through proper research. There are limitless resources online, from YouTube videos to the assembly videos provided by your seller.

You can also ask for support from their customer and tech service. Don’t hesitate to ask questions and let them assist you.

Lastly, there are some groups and forums online where you can ask questions. Fellow users within the community can help you address problems and troubleshoot.

What Is a Jewelry Engraving Machine?

A jewelry engraving machine is a device that etches characters on jewelry. It could be patterns, logos, words, or numbers.

Jewelry engraving machines are great for etching PERMANENT designs on the surface of the materials. They add intricate details, making the piece more unique and personalized.

How Does a Jewelry Engraving Machine Work?

A jewelry engraving machine uses laser technology to etch characters. If you’re using a pen tool, most designs are free-hand, and you can also engrave your penmanship.

Don’t worry if you’re not a free-hand artist, though! Most advanced engraver machines use computers to operate the laser.

You can use existing artwork or sketch an original piece and export it to the software, and the machine will command the laser head to do its thing. It’s pretty cool!

What Are the Different Types of Jewelry Engraving Machines?

The two main types of jewelry engravers are manual and computer-numeric-controlled (CNC).

As the terms suggest, the manual requires you to operate the laser tool yourself. These are the pens and old-school machines that don’t have software compatibility.

Meanwhile, CNC machines are more HI-TECH. A computer system controls the jewelry engraver, making the outputs more precise and high-quality.

How to Clean and Maintain a Jewelry Engraving Machine

Of course, you want your jewelry engraver to LAST LONGER. And that requires maintenance efforts on your end.

Your machine and tool will probably have a maintenance manual for your guidance. Manufacturers know best about machine care, so don’t ignore their words!

1. Clean the Mirrors

Laser machines have reflective and focus mirrors. Reflectivity is crucial in producing a crisp image.

Over time, smoke can fog the mirrors and DECREASE the performance quality of your engraving tool. It may also affect the laser itself.

Regularly checking up on your mirrors will help with better outputs.

2. Check the Lens

Similarly, the lens of your jewelry engraving machine can be affected by all the smoke. Cleaning it is also essential, but it doesn’t have to be as regular as the mirrors.

Here’s how you can clean the lens:

- Carefully remove everything that covers the lens (blow tube, pressure rings, cover)

- Clean the dust particles on the lens using a blowing balloon

- Carefully wipe the lens with a special cleaner/alcohol (don’t double-wipe if the cotton ball has already collected dust)

- Correctly re-install the parts you removed (blow tube, pressure rings, cover)

Handle the lens of your engraving tool as gently as you can. AVOID scratching the coating or roughly wiping the surface. Any scratch, no matter how small, will affect the quality of your jewelry engraver.

3. Clean the Cooling System

The cooling system is a vital part of any laser engraver tool. Since a laser heats, it needs a system to cool it down during use. If your coolers are faulty, the quality will follow.

Here’s a general idea of how to clean the cooling system:

- Clean the water and circulating tanks once a week

- Use clean water (pure or distilled) below 35 degrees Celsius

You might think, are all these necessary? Yes! The quality of your water affects the laser tube and other parts of the engraver. If it’s dirty with debris, it will reflect.

The temperature is also necessary since the purpose is to cool down the engraver tool. If the water is hot, then what’s the point?

And finally, always ensure that there’s circulating water within your engraver BEFORE starting the process. Although safety features might stop the system, it pays to be vigilant.

4. Occasionally Observe Its Performance

Even the best jewelry engraving machines sometimes falter – that’s just how a mechanical tool works! The easiest way to check for problems is to observe the performance.

It might be time for a check-up if you notice ABNORMALITIES, especially behaviors that weren’t present before.

It’s not wrong to do it yourself if you can, but I suggest taking it to an expert if you’re unsure. We want to avoid further damage.

Part of the regular observation is to check the hardware: check the screws if they’re in check, toggle the switches if they still work, and be on the lookout for loose parts.

5. Don’t Submerge in Water

You probably know this already, but NEVER SUBMERGE your engraver in water. It’s not the right way to clean a mechanical tool!

Use a damp cloth to wipe the external parts of the engraver machine and gently dust away the debris. The exterior doesn’t need a deep clean, anyway.

Frequently Asked Questions (FAQs)

If you still have questions about the topic, here is the most frequently asked questions article section!

What Kinds of Jewelry Can You Engrave?

You can engrave almost all kinds of jewelry made with metal, such as stainless steel, gold, or silver. Any engraver usually works on all soft materials.

What Materials Can You Engrave With a Jewelry Laser Engraver?

A jewelry engraver can engrave on wood, leather, plastic, cardboard, acrylic, paper, food, fabric, glass, rubber, etc.

You can also deal with metal if you have a more powerful machine. Some machines can also cut.

How Much Does a Laser Engraving Machine Cost?

A laser engraving machine can cost from $400 to $10,000. It depends on the kind, brand, and quality.

Of course, those above $5,000 are usually high-end and for professional use.

What Kind of Laser Is Needed for Engraving Metals?

The best laser type to engrave jewelry made with metal is a 50-watts fiber laser. That’s the power sufficient to produce high-quality and precise results.

Other laser types lower than this can also engrave on metal, but it’s often not as good or crisp. I strongly recommend investing in fiber lasers if you’re running a business.

Conclusion

I hope this list helped you find the best jewelry engraving machine for you. If there’s one takeaway I want you to have, it is that there’s no one-size-fits-all machine for everyone.

The best jewelry engraver still depends on you. Use these suggestions and considerations to find the appropriate tool or machine that checks all your boxes.

There’s something for you in the market, cheap or expensive, hobby or business. Proper research goes a long way. Good luck!